4 L/D Options. 6 L/D Options. 4 L/D Options. 3 L/D options. 3 L/D Options. HOWDEN COMPRESSORS. WRV compressors set the standard against which industry. Conditions) then the MVi manually adjustable system will be entirely satisfactory. With lower pressure. Food Processing Equipment Sells Used Ammonia Screw Compressors and Booster Compressors By Reco, Reco/Howden, Reco/Frick, and Howden.

Tilting pad thrust bearing • 1. 1 Issued: Summer 2013 Howden Compressors Ltd TECHNICAL BULLETIN www.howden.com/compressors HYDRODYNAMIC BEARINGS: UNLIMITED BEARING LIFE – LOWER COST OF OWNERSHIP The Howden WRV range of process gas and refrigeration oil injected rotary screw compressors uses thrust bearings as standard sleeve type journal bearings and as a tilting pad option. © Howden Compressors Ltd.

All rights reserved. 2013 BY UTILISING HYDRODYNAMIC TILTING PAD BEARINGS COMBINED WITH THE HYDRODYNAMIC SLEEVE BEARINGS, THE OPERATIONAL TIME CAN BE UNLIMITED. Installations working 24/7 in the most arduous applications have given more than 150,000 + hours without replacement. Howden’s proven tilting pad bearing design, with more than 45 years experience in the field, does not have a L10 life limit, and therefore does not require to be maintained after any specified period. Super Squat Simulator Game No Download. Extrator De Email Fox Serial. Howden’s tilting pad bearing design has centre mounted pads to distribute the load equally, extend the bearing life and offer bi-directional rotation.

The pivot pad design ensures that there is foolproof assembly which minimises stock holding. Maintenance and downtime is minimised in the costs of ownership, and reliability is greatly improved. The complete tilting pad bearing assembly is mounted in a self contained encapsulated bearing housing, (as shown in the sectional view to the right) incorporating fully flooded thrust plates and bearings, preventing gas flashing, and excellent pressurised positive oil film integrity at all operating conditions. The continuous flow of oil across the pads must be maintained at the relevant pressure, cooled and filtered, to ensure unlimited life.

TILTING PAD BEARING DESIGN FEATURES Centre mounting pivot pads ensure foolproof assembly, minimises stocks, and are capable of bi-directional running. Tilting pad thrust bearing and housing highlighted in green colour. • 2© Howden Compressors Ltd. All rights reserved. 2013 Technical Bulletin TILTING PAD THRUST BEARINGS TILTING PAD DESIGN TILTING PAD BEARINGS ARE FITTED WITH INDEPENDENT ACTIVE LOAD AND REVERSE LOAD BEARING ROWS. THE DESIGN LOAD CAPABILITY IS GREATER THAN THE MAXIMUM OPERATING RATINGS OF THE COMPRESSOR FRAME. The individual thrust pads are fitted as a complete assembly.

The pad shape is designed to give enhanced oil circulation and high load capability. The thrust pad profile is designed to minimise power loss whilst maintaining load carrying capacity. The pads are manufactured steel faced with tin based whitemetal babbitt and are available in alternative alloys, dependent on the application. The pads are mounted in the one piece carrier ring and are designed to give positive retention and simplified assembly within the thrust plate and pad assembly. Left: Double wall WRV casing with inboard tilting pad and thrust bearings fitted.

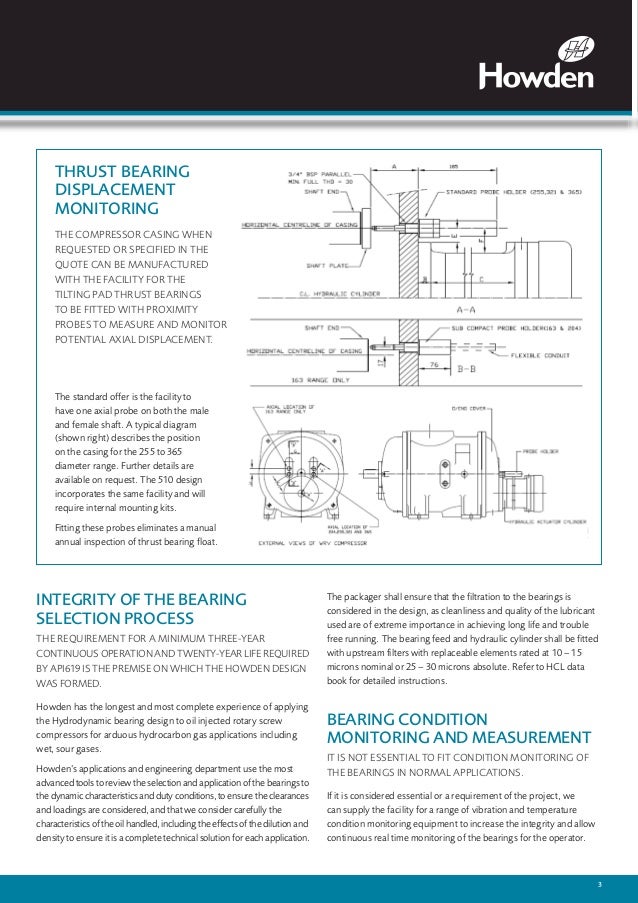

Thrust collar and outboard bearing prior to assembly. • 3 THRUST BEARING DISPLACEMENT MONITORING THE COMPRESSOR CASING WHEN REQUESTED OR SPECIFIED IN THE QUOTE CAN BE MANUFACTURED WITH THE FACILITY FOR THE TILTING PAD THRUST BEARINGS TO BE FITTED WITH PROXIMITY PROBES TO MEASURE AND MONITOR POTENTIAL AXIAL DISPLACEMENT. INTEGRITY OF THE BEARING SELECTION PROCESS THE REQUIREMENT FOR A MINIMUM THREE-YEAR CONTINUOUS OPERATION AND TWENTY-YEAR LIFE REQUIRED BY API619 IS THE PREMISE ON WHICH THE HOWDEN DESIGN WAS FORMED.

Howden has the longest and most complete experience of applying the Hydrodynamic bearing design to oil injected rotary screw compressors for arduous hydrocarbon gas applications including wet, sour gases. Howden’s applications and engineering department use the most advanced tools to review the selection and application of the bearings to the dynamic characteristics and duty conditions, to ensure the clearances and loadings are considered, and that we consider carefully the characteristics of the oil handled, including the effects of the dilution and density to ensure it is a complete technical solution for each application. The packager shall ensure that the filtration to the bearings is considered in the design, as cleanliness and quality of the lubricant used are of extreme importance in achieving long life and trouble free running. The bearing feed and hydraulic cylinder shall be fitted with upstream filters with replaceable elements rated at 10 – 15 microns nominal or 25 – 30 microns absolute. Tamil Fusion Songs For Dance Free Download. Refer to HCL data book for detailed instructions.

BEARING CONDITION MONITORING AND MEASUREMENT IT IS NOT ESSENTIAL TO FIT CONDITION MONITORING OF THE BEARINGS IN NORMAL APPLICATIONS. If it is considered essential or a requirement of the project, we can supply the facility for a range of vibration and temperature condition monitoring equipment to increase the integrity and allow continuous real time monitoring of the bearings for the operator. The standard offer is the facility to have one axial probe on both the male and female shaft. A typical diagram (shown right) describes the position on the casing for the 255 to 365 diameter range. Further details are available on request. The 510 design incorporates the same facility and will require internal mounting kits. Fitting these probes eliminates a manual annual inspection of thrust bearing float.